It’s been a long time since 3D printers became available and started allowing people to create 3D objects in the real world right from their own homes.

If you’re interested in knowing what a 3D printer is, how it works, how much it costs, and what you can do with it, you’ve come to the right place.

What is a 3D printer?

A 3D printer is a device that can create physical objects from digital files. The result is usually plastic. The edges may be rough and often only have one color. Despite these limitations, holding a copy of a 3D model in the real world makes it easy to know what works and what doesn’t.

While recreating lost or damaged parts is useful, 3D printers can also create enough parts to assemble an entire product. This technology is great for rapid prototyping, allowing quick changes to perfect a design before using expensive injection molding for high-volume production.

And 3D printing is also finding a place in commercial manufacturing. When producing small batches of products, 3D printing high-quality, but relatively slow and expensive components sometimes makes more sense than traditional methods with high initial costs and low unit costs.

How does a 3D printer work?

The most common 3D printer design, Fused Deposition Modeling (FDM), is similar to an inkjet printer. The FDM print head moves from side to side, depositing material on a moving platform. While inkjet printers spray ink droplets onto paper, 3D printers expel hot plastic onto a glass or metal plate.

Two computer-controlled motors direct the flow of plastic along the length and width of the finished object, one for the print head and one for the build plate. To create height, a third motor raises the rail on which the print head slides.

On the downside, 3D printing is a slow process compared to traditional manufacturing techniques, sometimes taking hours to create an object down to the third dimension. You can make it faster by extruding more material at once, but this will increase the layer height and result in a rough-feeling print. Vertical curves and angles also have stages, rather than the smooth surfaces and flat planes of most manufactured products.

The second most popular type of consumer 3D printer uses light, not heat, to form shapes in plastic. Known as 3D resin printers, this type uses UV light to project images onto liquid resin that reacts to those wavelengths and hardens.

3D resin printing is often faster, curing entire layers at once. However, UV resins are usually not as durable as the thermoplastics used for FDM 3D printing.

Specialty FDM filaments include more durable plastics, as well as some types of metal, glass, ceramic, and even wood. 3D printer parts have the appearance and some characteristics of these materials. With special 3D printers, it is possible to create objects from various materials, even cheesecakes.

What can a 3D printer make?

Commercial 3D printers can produce almost anything. Some 3D printers use powerful lasers to melt metal, producing strong components for use in rockets and other powerful machines.

Consumer-grade 3D printers are limited in size and materials. The size of the build plate determines the maximum length and width of a part, while the height of the printer influences the height of the 3D printed object.

In most cases, 3D printing fits in the palm of your hand. Larger consumer 3D printers can handle objects larger than one cubic foot. It is also possible to create a large object by assembling several smaller parts.

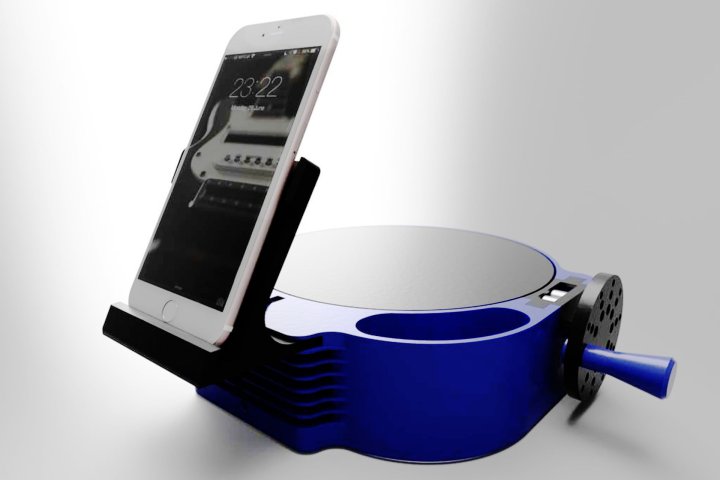

Some of the most popular 3D objects include a whistle, a phone holder with a manual turntable for scanning objects in 3D, a smart digital sundial that uses sunlight to cast a shadow that shows the time in easy-to-read numbers, and a mini octopus with flexible hinged legs that requires no assembly.

The possibilities are endless. For example, Thingiverse is one of the largest libraries of 3D objects designed for 3D printing, with over 2.5 million digital files — and most of them are free.

With the advent of generative AI, it is now possible to create 3D objects with text instructions. Currently, AI does not create designs that are optimized for 3D printing, so you will need to convert the files to a compatible format and process them through a 3D printing application before use.

How much does a 3D printer cost?

For around $300, you can get a very good consumer 3D printer. If you’re a frequent printing enthusiast, $500 to $1,000 will get you a much faster and larger 3D printer. Commercial 3D printers range in price from a few thousand dollars to over $1 million.

Be aware that you will need supplies and may want accessories for your 3D printer, so prepare to budget more for those additional costs. FDM filament and UV resin are relatively cheap, but sold in bulk, so you’ll spend at least $20 to get the necessary supplies.

Accessories include enclosures to reduce FDM 3D printer noise, better made plates, cooling fans to enable faster printing, UV lamps to harden the resin, and tools for 3D printer cleaning and maintenance. You usually don’t need any accessories to get started, and some 3D printers come with a small amount of filament or resin to make the first few prints.

3D printers open up the potential to create replacement parts cheaply, duplicate designs available online, or prototype new products that don’t yet exist. This amazing technology has been around for decades, but has only become affordable and easy to use in recent years.

If you haven’t explored 3D printing recently, it’s time to take another look. If you’re new to 3D printing, now is a great time to start.

Editor’s Recommendations